Production Management System

In terms of production management solutions, we are both bold and resourceful. Solving your problem and hustling is what we love to do. We conceptualize and create solutions which are relevant to the present & future needs.Production management system is the basis of modern factory information management for safe production, we establish the production management system and assist enterprises in fulfillment of business plans, construction of their production orders, deployment of production resources, assurance of safe production and realization of their production goals,Pharma, Food industries, Beverages industries, heavy asset processing industries, such as power generation, chemical industry, iron ,steel and nonferrous metal to constantly improve the corporate level of intelligent plant production and better the enterprise management performances.

INTRODUCTION

- It is defined as planning , implementation and control of industrial production process to ensure smooth and efficient operation. production management techniques are used in both manufacturing and service industries.

- Simply, production management is a process of planning, organizing, directing and controlling the activities of the

production function.

KEY FEATURES

- Real time efficiency calculation

- Downtime analysis

- High speed production counter

- Cloud based

- monitoring(Application based)

- Report generation

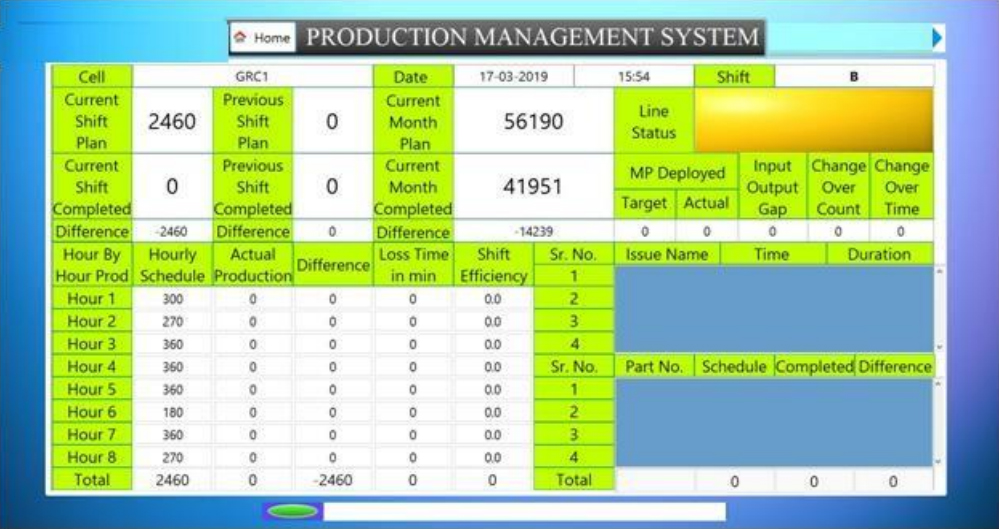

Functional Specifications of PMS

- Display Screen –

- Rotating display with 12 seconds interval for each cell display

- The Line Status indicator will be yellow if no input is received for 5 minutes. Green, if the line is running and red when the line is stopped

- The application is authenticated with User credentials.

- Access to modify the REPORT, SETTING, CONFIGURATION AND EMAIL are

only with the admin user. - SELECT the date and click on EXPORT Button to get the required report.

- REPORT can be emailed to the list of email IDs configured

REPORT GENERATIONS

There are various types of reports that are made using PMS ,stated below

- Daily reports

- Monthly reports

- O.E.E. reports

- Manpower reports

- Application reports

- Downtime reports

- Changeover reports

- Hourly reports

TANGIBLE BENEFITS

- Better management of equipment to increase efficiency in manufacturing and production

- Improved allocation of resources to reduce labor costs

- Management of data in one central system to eliminate errors or duplication

- Improved procurement procedures to decrease the cost of materials

- Enhanced planning and control to shorten work-in-progress times

INTANGIBLE BENEFITS

- The ability to compare desired output with actuals

- Better production control

- Standardized procedures

- Faster accessibility

- Improved monitoring

- Error-proofing enhanced, increased accuracy of data

- Multiple systems acting as one central system with full-transparency

- Analysis of production

Our customized software for Hella contains

- User friendly interface to place the target for each line

- Downtime analytical report

- Real time dash board for hourly data monitoring

- Change over report

- Automatic emailing

- Alarm and alerts generation

- Online fault monitoring

- High speed counter for high speed lines

- Automatic report generation for OEE

- indication of No. of lines in red(inactive lines)

- Man hour calculation

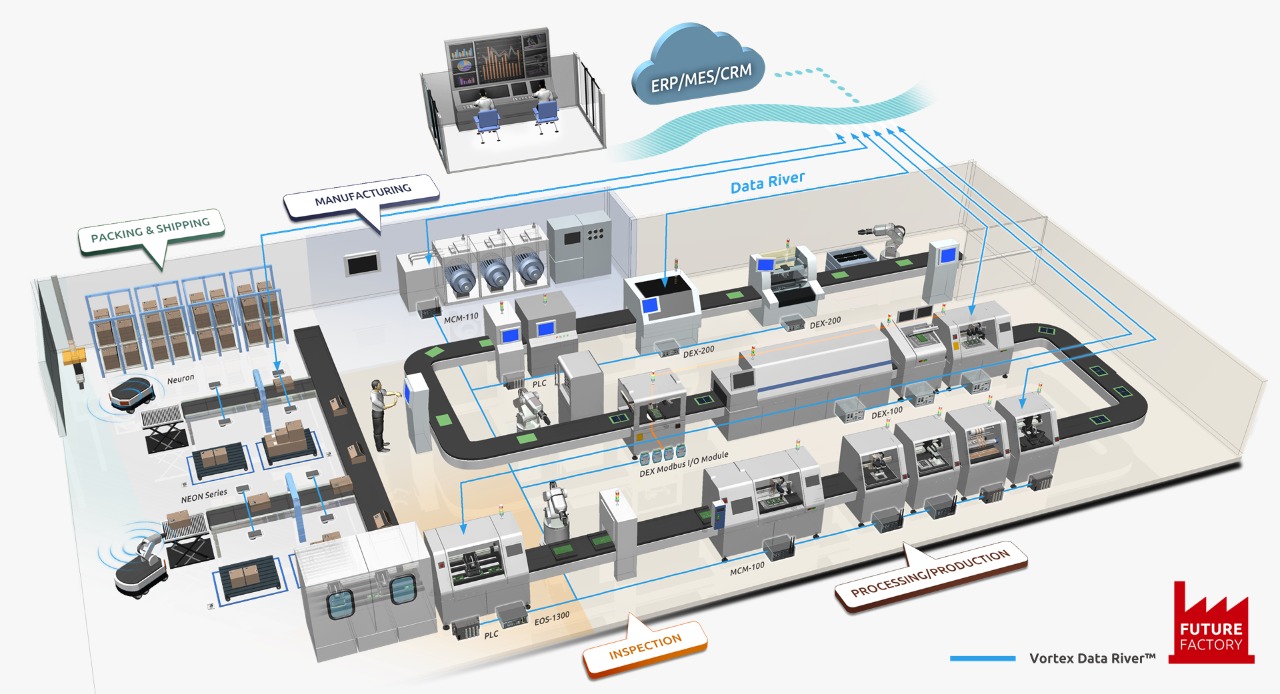

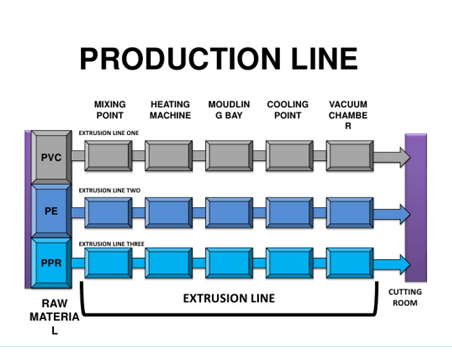

Production Line Management System

- Easily Monitor Line Status

- Identify Bottle Neck

- Track Setup Time Accurately

- IOT Based Data logging

- Graphical lay out of Production Line

- Machine Vision Systems

- Maintenance Alerts and Alarms

Machine Run Time System

- Over all Equipment Effectiveness(OEE)

- Data Acquisition

- Operators or worker sutilization

- Down time Analysis

- Daily Efficiency report generation

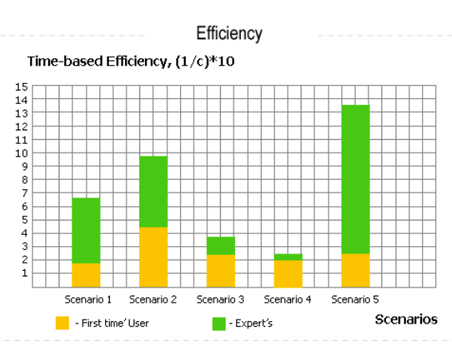

Efficiency Calculator

- Real time efficiency Calculation

- Down time Analysis

- High Speed Production Counter

- Cloud Based Monitoring (Application Based)

- Report Generation

Add-ons

- Alarm and Alerts Generation

- Online Fault Diagnostics

- Wireless Connectivity

- PLC Server and Analytics

- Automatic E-mailing

- Machine Vision System (Surveillance)