Downtime Monitoring

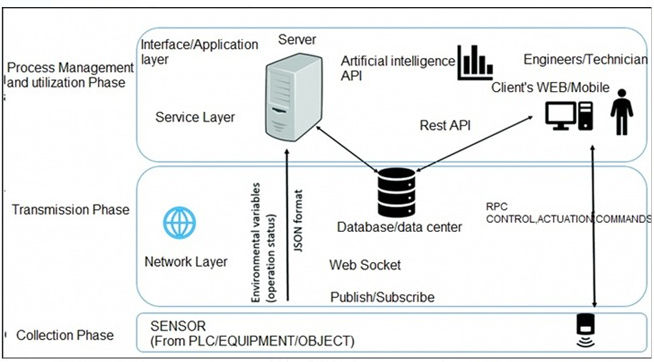

IOT based downtime management system will be sensing the data from PLC (or any hardware) of the organizations and then this data will be transmitted to server for processing, server will transmit data to the web app indicating alerts/warnings and downtime analysis.

Downtime Analysis System Features

Our Downtime Analysis Systems are based upon idea of industry 4.0. The method used for data actuation helps our customer attain productivity, quality and accuracy of the products and enable them to upgrade their existing technology with latest one.

Key Features

- High Accuracy

- Real time information

- Increased Productivity

- Increased Delivery of service

- Increased Consistency

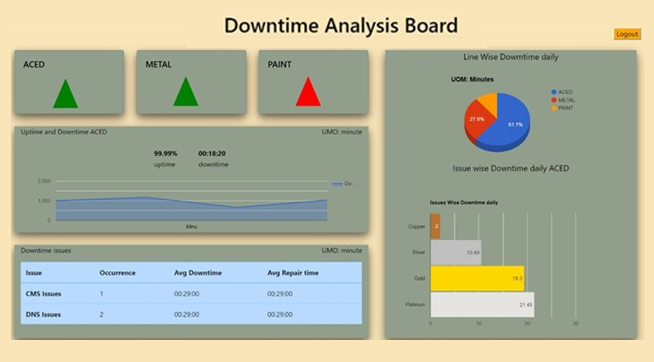

Downtime Analysis Board:

This is the picture of downtime analysis systems installed at one of our client , in this system user can check the downtime logs for various units such as ACED, METAL, PAINT if a system is down then that will be indicated by red if it is working properly then it will be green, it also provides day wise breakdown graph for all the departments and we can also monitor average downtime for various CMS Issue and, DNS issue with the number of occurrences, average downtime and average repair time and on right side of dashboard we are having a graph of line wise downtime of everyday followed by issue wise downtime of every day.

In this system user can monitor the status of all downtime remotely with availability of total downtime.

ADD ONS

- GSM/SMS Integration

- GPS Integration

- IoT Enabled Remote Access

- Cloud Based Downtime Analysis

- Centralized Downtime Analysis

- Critical Alarm Generation

Functional Requirements:

Downtime Analysis Software

The application uses LABDAC device collects the data from all the lines through the sensors installed on each machine, gives to centralized software.